Dual Vacuum Super Conductive Tube (DVT) Introduction

①Working Principle of Dual Vacuum Super Conductive Tube

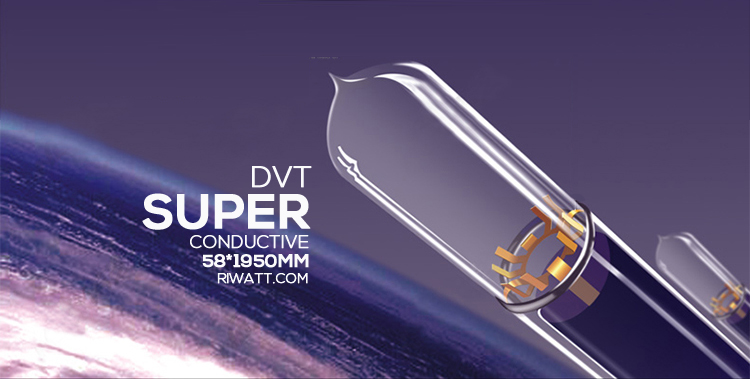

Dual Vacuum Super Conductive Tube ,which is made of high-light transmittance borosilicate ultrahard glass tubes by special process, is formed by a double-layer tube and a single-layer tube.

A high-vacuum sandwich layer is arranged between the inner tube and the outer tube, the inner cavity of the inner tube is low-vacuum, and the double-vacuum closed heat collection and heat transfer element is the heat collector.

The assembly consists of an outer glass tube having a multi-metal carbonizing sunlight-absorbing film(SS-ALN/CU) characterized by high-temperature stagnation resistance, with superior aging resistance, an inner glass tube, a compatible spiral suspension core, loading with conduction working fluid.

One end of the tube is the solar collector tubes, namely the evaporation section, while the other end is the condensing section, namely the heat exchange section;

When the evaporation section absorbs solar energy and is heated, the liquid in the suspension core is gasified, under the action of pressure difference, the steam flows to the condensing section at a sound velocity, releases heat energy and then is condensed into liquid, the liquid flows back to the evaporation section along the tube wall, and the circulation goes again and again.

By utilizing gasification of the working liquid in the tube, the heat is continuously transferred from one end to the other end of the tube in the liquidation phase change super-conduction circulation process.

② The heat transfer of the working liquid in the DVT tubes includes four links:

1. At the heating section of the heat tube, the working liquid in the tube is gasified by an external heat source;

2. Due to pressure difference between the heating section and the condensing section of the tube, the steam moves toward the condensing section;

3. At the condensing section, the heat released by the steam in the tube is brought away by the external cold medium, and the steam is condensed into liquid which flows back to the evaporation section by gravity;

4. Under the action of the absorption suspension core, the condensing liquid is re-heated and gasified, and the circulation goes round and round.

③ Dual Vacuum Super Conductive Tube Basic Characteristics

1). Superior thermal conductivity.

In the heat tube, the heat is transferred mainly by phase change of the working liquid and the flowing of the steam, the thermal resistance is small, so that the heat tube has quite high heat conducting capability; and compared with the metal with higher heat conductivity such as silver, copper, aluminum, etc., the heat tube with unit weight can transfer more heat;

2). Superior isothermal property.

The steam in the inner cavity of the heat tube stays in the saturated state, so when the steam flows from the evaporation section to the condensing section, there is little pressure drop as well as temperature drop;

3). Variable density of heat flow.

The density of heat flow in the inner tube can be changed by modifying the heating surface of the condensing section or the evaporation section..jpg)

Dual Vacuum Super Conductive Tube (DVT) Introduction

①Working Principle of Dual Vacuum Super Conductive Tube

Dual Vacuum Super Conductive Tube ,which is made of high-light transmittance borosilicate ultrahard glass tubes by special process, is formed by a double-layer tube and a single-layer tube.

A high-vacuum sandwich layer is arranged between the inner tube and the outer tube, the inner cavity of the inner tube is low-vacuum, and the double-vacuum closed heat collection and heat transfer element is the heat collector.

The assembly consists of an outer glass tube having a multi-metal carbonizing sunlight-absorbing film(SS-ALN/CU) characterized by high-temperature stagnation resistance, with superior aging resistance, an inner glass tube, a compatible spiral suspension core, loading with conduction working fluid.

One end of the tube is the solar collector tubes, namely the evaporation section, while the other end is the condensing section, namely the heat exchange section;

When the evaporation section absorbs solar energy and is heated, the liquid in the suspension core is gasified, under the action of pressure difference, the steam flows to the condensing section at a sound velocity, releases heat energy and then is condensed into liquid, the liquid flows back to the evaporation section along the tube wall, and the circulation goes again and again.

By utilizing gasification of the working liquid in the tube, the heat is continuously transferred from one end to the other end of the tube in the liquidation phase change super-conduction circulation process.

② The heat transfer of the working liquid in the DVT tubes includes four links:

1. At the heating section of the heat tube, the working liquid in the tube is gasified by an external heat source;

2. Due to pressure difference between the heating section and the condensing section of the tube, the steam moves toward the condensing section;

3. At the condensing section, the heat released by the steam in the tube is brought away by the external cold medium, and the steam is condensed into liquid which flows back to the evaporation section by gravity;

4. Under the action of the absorption suspension core, the condensing liquid is re-heated and gasified, and the circulation goes round and round.

③ Dual Vacuum Super Conductive Tube Basic Characteristics

1). Superior thermal conductivity.

In the heat tube, the heat is transferred mainly by phase change of the working liquid and the flowing of the steam, the thermal resistance is small, so that the heat tube has quite high heat conducting capability; and compared with the metal with higher heat conductivity such as silver, copper, aluminum, etc., the heat tube with unit weight can transfer more heat;

2). Superior isothermal property.

The steam in the inner cavity of the heat tube stays in the saturated state, so when the steam flows from the evaporation section to the condensing section, there is little pressure drop as well as temperature drop;

3). Variable density of heat flow.

The density of heat flow in the inner tube can be changed by modifying the heating surface of the condensing section or the evaporation section.